Choosing a battery for your electric vehicle is a very important step for your electric vehicle. Because if you select the wrong battery pack. And it will not match the drivetrain and you will not get the desired performance and range, but the risk of damage to the drivetrain component also increases. Even your battery can also be damaged. How To Select Battery For Electric Car Conversion?

These are some following factors that help you to select a Battery For Electric Car Conversion

- Required Driving Range.

- Battery Power Calculation.

- Operating Temperature And Battery Chemistry.

- Spatial Constraints For The Battery Pack.

Required Driving Range.

The range that you want for your electric vehicle determines the final size of your battery. That’s why you have to decide on a theoretical range whose capacity you can convert into KWH. This is a key that has to be kept in mind while designing a battery.

How much range you have to keep during charging depends on the battery capacity you need. That means a Tesla car uses 0.2 kWh per km. So, to find out what capacity battery you need, convert your desired range in km and multiply by factor 0.2. This will give you a rough idea of how much battery capacity you need.

Battery Power Calculation.

The amount of power that you want for your electric vehicle determines the type of battery that you will fit in the battery pack.

The peak power that the motor demands from the battery pack depend on the excess discharge of the battery current.

The motor which uses continuous power while running the electric vehicle decides the continuous discharge current of the battery.

Battery Power Calculation to select battery for electric car conversion

To make it clear that the calculation is involved. We have two prepared examples.

| Battery Power Calculation. | Battery Power Calculation. |

| 20 batteries serial, 1 battery parallel. | 20 batteries serial, 4 batteries parallel. |

| Peak discharge: 30A per battery. | Peak discharge: 30A per battery. |

| Continuous discharge: 15A per battery. | Continuous discharge: 15A per battery. |

| The maximum discharge power of the battery pack is 1 battery parallel x 30A = 30A. | The maximum discharge power of the battery pack is 4 batteries parallel x 30A = 120A. |

| The continuous discharge power of the battery pack is 1 battery parallel x 15A = 15A. | The continuous discharge power of the battery pack is 4 batteries parallel x 15A = 60A. |

To quickly find out how many modules are required to be packed in the battery pack you can use this power battery calculator.

Operating Temperature And Battery Chemistry.

It is very important to know in which environment temperature you are going to run your electric vehicle because below 0 degree Celsius can affect the chemistry of your batteries. There are two best chemistry batteries for electric vehicles. The lithium-ion (Li-Ion) batteries and the lithium-iron-phosphate (LiFePO) batteries.

The lithium-ion batteries have operated between the temperature of 10 – 60 degrees Celsius. And the life batteries have operated between the temperature of -10 – 60 degrees Celsius.

It is very important to keep both chemistries in their operating range. If we use it outside its range, then it can also reduce the lifespan and capacity of the battery pack. Its dangerous thing is that when its temperature goes above 60 degrees, it is only when fire or explosion can happen.

Spatial Constraints For The Battery Pack.

Available battery pack space will influence your choice of battery chemistry. Lithium-ion battery chemistry has a higher energy density than LiFePo. That means life will take more time to reach the same output than lithium-ion.

The voltage determines the total capacity and power of your battery pack. If you’ve hooked up any other drive trains components like motors and controllers, you’ll know how much voltage you need. Each battery connected serially adds to the total voltage.

Now we are going to see some formulas to calculate the power and capacity of the battery to select a battery for electric car conversion.

| Capacity | Peak Power | Continuous Power |

| capacity per battery x number of batteries connected in parallel x nominal voltage | peak current per battery x number of batteries connected in parallel x nominal voltage | continuous current per battery x number of batteries connected in parallel x nominal voltage |

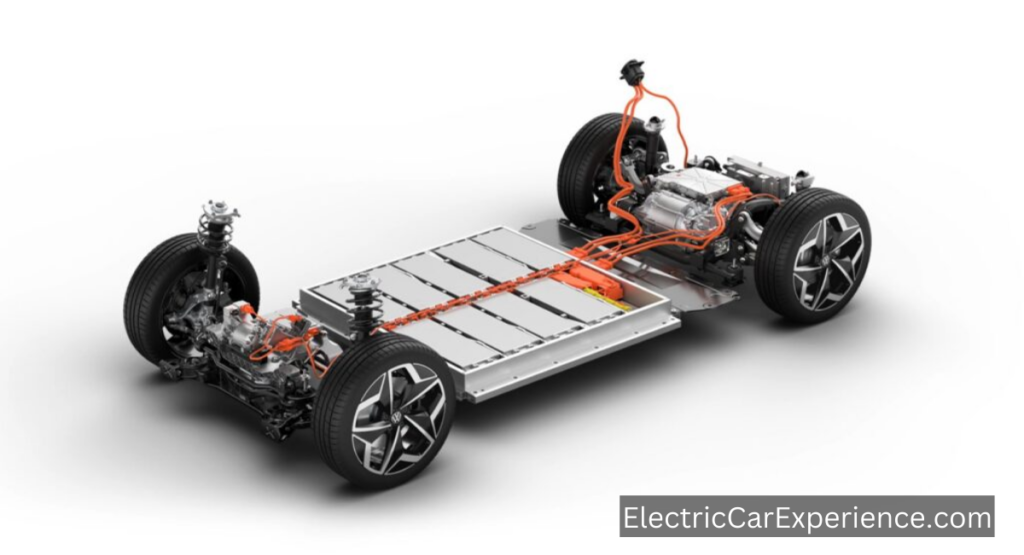

Below Image shows the Process of Selecting a Battery for Electric car Conversion

Some Battery Options to Select a Battery for Electric Car Conversion

- Lithium-ion Battery Options to Select Battery for Electric Car Conversion

| Battery Model | Energy Density (Wh/kg) | Capacity (kWh) | Voltage (V) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| LG Chem NCM 622 | 200-240 | 40-100 | 3.6-4.2 | 200-400 | 8,000-15,000 |

| Tesla Model S | 180-200 | 60-100 | 350-400 | 540-625 | 15,000-25,000 |

| Panasonic NCR18650B | 200 | 3.4-3.5 | 3.6-4.2 | 45-50 | 400-500 |

- Lead-Acid Battery Options to Select Battery for Electric Car Conversion

| Battery Model | Energy Density (Wh/kg) | Capacity (kWh) | Voltage (V) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| Trojan T-105 | 80-100 | 5-7 | 6-12 | 28 | 100-150 |

| Crown CR-235 | 75-85 | 7-8.5 | 6-12 | 30-31 | 150-200 |

| Optima D34M | 75-85 | 3.3 | 12 | 19 | 200-250 |

- Lithium Iron Phosphate (LiFePO4) Battery Options to Select Battery for Electric Car Conversion

| Battery Model | Energy Density (Wh/kg) | Capacity (kWh) | Voltage (V) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| CALB SE130AH | 130-140 | 7-8 | 3.2-3.3 | 55-60 | 800-1,000 |

| Winston LiFePO4 | 100-120 | 40-200 | 3.2-3.3 | 100-500 | 1,500-3,000 |

| Headway LiFePO4 | 100-120 | 10-30 | 3.2-3.3 | 35-120 | 600-1,20 |

- Nickel-Metal Hydride (NiMH) Battery Options to Select Battery for Electric Car Conversion

| Battery Model | Energy Density (Wh/kg) | Capacity (kWh) | Voltage (V) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| Panasonic EV | 60-70 | 4-10 | 1.2 | 50-100 | 500-1,000 |

| Sanyo HR-AAU | 60-70 | 0.06 | 1.2 | 0.1 | 2-5 |

| Energizer NH22 | 60-70 | 0.03 | 1.2 | 0.05 | 1-3 |

- Solid-State Battery Options to Select Battery for Electric Car Conversion

| Battery Model | Energy Density (Wh/kg) | Capacity (kWh) | Voltage (V) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| QuantumScape | 400-500 | 10-100 | 3.2-3.8 | 20-200 | N/A |

| Solid Power | 300-400 | 20-80 | 3.2-3.8 | 50-150 | N/A |

| Ionic Materials | 200-300 | 5-50 | 3.2-3.8 | 25-100 | N/A |

- Zinc-Air Battery Options

| Battery Model | Energy Density (Wh/kg) | Capacity (kWh) | Voltage (V) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| NantEnergy Zinc-Air | 150-200 | 10-30 | 1.2 | 70-150 | 1,000-2,000 |

| Eos Aurora | 100-120 | 20-50 | 1.2 | 150-300 | 1,500-3,000 |

| Fluidic Zinc-Air | 80-100 | 5-10 | 1.2 | 40-70 | 500-1,000 |

- Sodium-Ion Battery Options

| Battery Model | Energy Density (Wh/kg) | Capacity (kWh) | Voltage (V) | Weight (kg) | Cost ($) |

|---|---|---|---|---|---|

| Faradion Na-ion | 80-100 | 5-15 | 2.2-2.5 | 70-120 | 800-1,500 |

| Aquion Energy | 70-90 | 10-30 | 2.2-2.5 | 100-200 | 1,200-2,500 |

| HiNa Battery | 50-70 | 5-10 | 2.2-2.5 | 80-120 | 700-1,200 |

Nissan Leaf Battery For Electric Car Conversion.

Jay’s Chevy S-10 needed a new electric vehicle battery conversion. The conversion was done from a bank of lead acid underneath the truck bed with a lithium-ion battery. Jay thought it was not worth it to replace it with the same battery, so he replaced it with a Nissan Leaf lead acid battery. So let’s take a look at how Jays converted a Nissan Leaf battery into a Chevy S-10.

First, he took out the whole battery. After getting all the car parts and batteries out he started salvaging the battery for himself. He placed both the replacement set of batteries in front of him, the lead acid battery and the equivalent lithium-ion battery. Then he converted the battery to a Nissan leaf acid battery and took the first test drive successfully. With a 48-leaf cell resembling the volume of old batteries.

Now, he had to add some additional battery management. During conversion, he needed more amps and 650 lbs less weight for the same power which is quite good.

The below videos shows Nissan Leaf Battery For Electric Car Conversion

Best Batteries For EV Conversion.

Some people say the battery is the most important part of an electric vehicle. It’s also the most expensive single component, with 20 to 30 percent of the vehicle’s net cost. We will also talk about how to do battery conversion for electric vehicles. But first, we talk about the best batteries for electric vehicle conversion.

Lithium-ion batteries are the best batteries for electric vehicle conversion because. The lithium-ion batteries have operated between the temperature of 10 – 60 degrees Celsius. And it is perfect for places where the temperature is not a problem. Lithium-ion battery chemistry has higher energy density currently available.

Now let’s take a look at important things about battery conversion for electric vehicles.

Important Things About Battery for Electric Car Conversion.

Veronika found an old car that happens to be a jeep wrangler. They removed the engine, defined the powertrain configurations, ordered e-motors and inverters, and how they arrived at the heart of the electric vehicle which is the battery. But the question arises: what’s the important thing about the battery for Electric Car Conversion?

When picking a battery for a conversion project you have several restrictions like weight, space, voltage, and cost. First, we talk about weight once a conversion is done you don’t want to exceed the electric vehicle’s weight too much. The second thing is space where you find all the batteries that you need. The third one is the voltage that has to be aligned with the e-motors inverter system that you pick.

The Above Image shows the steps to install a Battery for Electric Car Conversion

The last one is the cost. Maybe you want to look into a new battery or maybe you have some access to some scrape where you can reuse these batteries. There are different options out there.

So, let’s see where she finds space in their jeep for the batteries after removing the engine transmission gas tank and so on. The jeep has space on both sides of the drive shaft and also they have plenty of space in the engine component after all there is also a little bit of space where the original gas tank used to be. But one important thing is overall weight distribution that’s why they include the Jeep expert.

3 There are many different kinds of chemistry out there. There are only three major cell formats. The first one is the most famous cylindrical cells, which are used by Tesla and also in lucid motors. The second one is prismatic with a metal case that is used by BMW. The third one is the pouch cell. They just have a thin foil around them; they’re pretty flexible. These are used by Hyundai gm or for example Ford.

We see a lot of do-it-yourself and also companies that offer conversion kits based on cylindrical cells. For example, you can easily find used Tesla modules on eBay. Cylindrical cells also have some safety advantages in case of a thermal runaway on the cell level there is less of the chance for the fire to propagate throughout the whole.

Lithium Ion Battery Specification to Select Battery For Electric Car Conversion.

The lithium-ion battery has become very common today in consumer electronics. And these types of batteries are best for portable electronics with the best energy-to-weight ratio and when it is not in use then their battery also drains very slowly which is quite good. Lithium-ion batteries are also environmentally friendly. Now let’s talk about lithium-ion battery specifications for electric vehicles.

The image below shows the benefits of using a lithium-ion battery for Electric Car Conversion

Following are the specifications of lithium-ion batteries to select a battery for electric car conversion.

- A lithium-ion battery is installed in an electric vehicle which can easily run the vehicle for 200 – 300 miles on a single charge.

- The nominal voltage of lithium-ion batteries is between 3.2 to 3.7 V.

- Lithium-ion batteries are lighter than other cells, which also slightly increases the range of the vehicle.

- Lithium-ion battery chemistry has a higher energy density than any battery technology today.

- Lithium Ion batteries also have a low self-discharge rate which is around 1.5-2%.

These are some specifications for lithium-ion batteries for electric vehicles. Now let’s see some features of lithium-ion batteries.

| Features Of Lithium Ion Batteries | Descriptions |

| VOLTAGE PER CELL | Lithium Ion batteries are placed parallel so that they provide the required amount of amp-hour (Ah). an Ahs range between a few amps or a hundred amps, It depends on the application that is required. The lithium-ion battery uses 3 2.3Ah cells in parallel which easily produces 7.8 Ah. And if you use 10 2.3 Ah cells in parallel, then it can easily produce up to 26 Ah. |

| CAPACITY | The nominal maximum charge rate of lithium-ion is 1c and the lithium polymer is about 2c. Currently, some cells can produce charge rates up to 10c. Select the right cell and you can have the Lithium Ion battery pack that will meet your requirements. |

| MAX CHARGE RATE | The maximum discharge rate of lithium-ion is 2c and the lithium polymer is about 3c. (Note: lithium-polymer discharge rate greater than 30c rate). |

| MAX DISCHARGE RATE | The maximum discharge rate of lithium ion is 2c and the lithium polymer is about 3c. (Note: lithium-polymer discharge rate greater than 30c rate). |

| DISCHARGE TEMPERATURE RANGE | The lithium-polymer and lithium-ion both have a limited discharge rate which is -20c – 60c. SWE selects empirical and chemistry data with an increased limit on discharge rate down to -50°c |

| STORAGE | The temperature rate recommended for storage is – 20°c to 60°c. (If the storage temperature goes below 20° C, then it will lose its capacity permanently). |

| Battery Pack Protection | The following things are provided by BMS: Battery Overcharge Protection (Most critical), – Battery Over-discharge Protection, – Discharge Over-current Protection, – Charge Over-current Protection, – Load, short-circuit Protection, and Inhibit 0V charging condition. |

| Charge Management | Charge Temperature Monitoring: – Pulse charging on board and Charge control can be set to a percent of capacity per customer requirement. |

| Recommended Max Currents | 8 Amps continuous, up to 20 Amp pulse for 30ms. (Note: 5 series to 10 series BMS an additional 4 current booster PCAs of 16 Amps per can be added allowing a total of 72 Amps per BMS.) |

Electric Car Battery Capacity Ah.

The electric vehicle battery is also known as a traction battery. You can also take an example of a lithium-ion battery. Lithium-ion battery chemistry has higher energy density currently available. And the Lithium Ion battery is very light due to which the overall weight of the vehicle also becomes light and that’s why its performance increases. There are most common batteries like lithium-ion, lithium-polymer, lead acid, and valve-regulated lead acid.

But now we are going to talk about electric car battery capacity Ah.

In general, most electric vehicle battery capacity ranges between 40 and 60 ampere hours. The ampere-hour rating refers to the power and longevity of the battery. It also tells you how long your battery can last without charging. The ampere-hour rating is for a large battery, such as a car battery, which is generally 20 hours.

Now let’s take a look at the most common types of battery in modern electric vehicles.

- Lithium-ion battery.

- Lithium-polymer battery.

- Lead acid battery.

- valve-regulated lead acid battery.

- Nickel-cadmium battery.

- Nickel metal hydride battery.

- Zinc-air battery.

- Sodium nickel chloride battery.

These are some most common batteries which are used in modern electric vehicles for better range and fabulous performance.

In the 1990s, the technology of lithium-ion batteries increased and then after a few years its demand also increased and it started being used in many things like portable electronics, laptop computers, mobile phones, and power tools.

As the technology of batteries is increasing, in the same way, the production of batteries is also increasing, due to which the price of batteries fell by 87% in 2019 since 2010 based on per kilowatt-hour. Vehicles that have a range of more than 250 miles like the Tesla Model S have become commercialized in the current segment of numerous vehicles.

Electric Vehicle Battery Size Comparison.

In this topic, we will compare the electric vehicle battery with the battery of the phone so that you can get an idea of the power of the electric car battery and it will be very interesting to compare the battery of the electric vehicle with the mobile battery and to look at our expectations of each. Now let’s see the electric vehicle battery size comparison with mobile batteries.

There is a pouch cell in your phone which is around 2.5ah to 5Ah. And if we look at the battery of an electric vehicle, then it would have been around 300Ah, and operate between 440V to 270V. Now you must have got a slight idea of how big the battery of an electric car is.

Mobile Phone Battery.

- When your phone’s battery is fully charged then it is close to 4.4 volts and when it is completely exhausted it means it shuts down completely then the mobile battery is close to 2.9 volts. When your mobile phone is with you, its temperature ranges from 15°c to 45°c. The battery management system in mobile phones monitors the temperature and voltage of the cells.

- Your phone’s battery can power your phone for nearly two days and when your phone’s battery runs out, it takes 30 minutes to charge your battery fully, till then you can also meet your friend.

- If your phone’s battery is about to degrade, you feel like this. your charging is getting finished in 12 hours, then you will get it replaced in a few months.

Electric Vehicle Battery.

- If we look at the battery of an electric car, its battery is made by connecting the cells in parallel and series. If you have to go out for work and the outside temperature is -20 degree Celsius, you can still take your electric vehicle out by turning it on without any problem.

- And if you have the same work in summer, that means the outside temperature is 45 degree Celsius, even then you can go by electric vehicle without any problem, that too by turning on the air conditioner.

- The battery of an electric vehicle is designed in such a way that it can last easily for 15 years, but the battery of the mobile phone or mobile phone has to be changed every two years.

Electric Vehicle Battery Recycling.

Many manufacturers are researching how to get the battery of an electric vehicle back to work after hitting the age of retirement.

There was an idea that could bring the electric car battery repurposed and that was if we make the same battery to power the home or in the building. or there is no definite answer to this once the battery is not recycled for a long time, then recycling it is impossible.

To know the answer to this, we go ahead and get more information. Let’s get some information about electric vehicle battery recycling.

As a General Rule, When the battery reaches the end of its working life, it is recycled, which typically involves separating valuable materials such as

cobalt and lithium salts, stainless steel, copper, aluminum, and plastic. Only up to 50% of the material is recycled in the battery pack of an electric vehicle.

But as electric vehicles are exploding, in a few years the manufacturers are thinking of improving them. VW has just recently announced a pilot plant for electric vehicle batteries Which will work on the target of recycling 97% of battery components. In this process, batteries will be shredded, dried, and then sieved. To recycle the valuable material that makes new batteries

The way the battery used to be useful for electric vehicles, in the same way very soon it is going to come into our useful life as well. If the battery is removed from the electric vehicle, then it can still be demanded in many works like energy storage in the electricity network, or in the home – a growing area of demand.

Now let’s take a look at the process of recycling electric car batteries.

- Storage of raw material.

- Dismantling of different parts.

- Smelting of raw material in the furnace.

- Extraction of valuable materials.

- Process of harmful fumes and gases.

Battery Technologies To Select Battery For Electric Car Conversion

Even if the lithium-ion battery establishes itself today as the preferred choice for the electric car there are nonetheless alternative technology available in today’s market some are very old such as lead acid batteries and some are new such as lithium-ion batteries we see various commercially successful electric vehicle models today via sport or economical models the battery pack design is closely related to the performance of an electric vehicle.

So, in this topic, you are wondering about battery Technologies for electric vehicles to select the battery for electric car conversion.

In Total, french physicist gaston plante invented the rechargeable lead battery in 1859. The technology is used to store energy through electromechanical processes since then it has made great progress. All the scientific work has had a similar goal to find the best possible compromise between the battery weight, storage capacity, production cost, recharging capacity, and environmental impact.

Especially when the time comes for it to be recycled the different types of electric batteries are lithium-ion batteries, hybrid nickel-metal batteries, lead acid battery solid-state batteries, nickel-cadmium batteries, and nickel metal batteries. The types of electric car batteries depend on the car system. The most popular electric car used lithium-ion batteries. The most suitable battery for hybrid electric cars is a hybrid nickel-metal battery.

The lithium-ion battery was the most widely used electric car. It was developed in the early 90s and gradually established itself as the leading technology in transportation and the consumer in the electronics industry. You might already be familiar with this because smaller versions of this are used in portable devices like mobile phones and even laptops however, the ones used in cars are much bigger and have higher capacity often referred to as traction battery packs.

Lithium-ion batteries have an immensely high-power-to-weight ratio making the vehicles more energy efficient. The battery performance is relatively better than others at high temperatures as well. This is mainly used due to its energy per weight ratio and essential consideration in electric car batteries. Lithium-ion batteries have higher energy density than lead acid batteries or nickel metal hydride batteries so it is possible to make the battery size smaller than others.

In other words, the smaller the weight of the battery the further the car can drive on a single charge the battery also has a low self-discharge level which means it is better and able to maintain its charge when compared to the other alternatives in addition to that most component of the lithium-ion batteries can get recycled this is a bonus for the electric car since they are made with the main motive saving the environment.

Types Of Lithium Ion batteries.

- Lithium-ion phosphorus (LFP).

- Lithium titanate (LTO).

- Lithium nickel manganese cobalt (NMC).

- Lithium manganese oxide (LMO).

- Lithium nickel cobalt aluminum oxide (NCA).

Advantages Of Lithium Ion Battery for Electric Car Conversion

Lithium-ion batteries are getting better as electric cars demonstrate lightweight lithium-ion batteries were first used correctly in electric vehicles in the pioneering tesla roadster manufactured from 2008 to 2012. It took roughly 3.5 hours to charge its 6831 lithium-ion cells which weighed one half a ton 1100 pounds and held 53 kilowatt hours of energy. They were fully charged and gave the car a range of over 220 miles.

The image below shows the advantages of a lithium-ion battery for Electric Car Conversion

Teslas have far better cells and a much greater range. A typical tesla model 3 has a 75 KWh battery, and half as much energy as a Roadster with just 4416 cells so they have much higher energy density and a range of 374 miles.

Disadvantages Of Lithium Ion Battery.

- Lithium-ion batteries are sensitive to high temperatures.

- If the battery is completely discharged, it can no longer be recharged.

- It is relatively expensive

The Nickel Metal Hybrid Battery for Electric Car Conversion

The nickel metal hydride battery, another variant of electric cars, is a hybrid car that contains battery power in fuel-powered engines. These cars mainly use hybrid nickel metal Batteries but these batteries are also compatible with battery electric vehicles. These kinds of batteries do not require any external power source to charge. The charging of the battery mainly depends on the car’s regenerative braking, speed, and wheels.

When compared to lithium-ion batteries nickel metal batteries have a better life cycle and are safer in case of intolerant use. However, these batteries have a higher self-discharge rate and are much more expensive, and generate a considerable amount of heat in high temperatures which is common in a car. These few shortcomings make nickel metal batteries a lesser choice for a vehicle whose battery needs to be charged from an external source.

This is also the main reason these batteries are used in hybrid cars with performance similar to nickel-cadmium technology nickel metal hybrid accumulators have seen more prolonged success due to their absence of heavy metal. This portable rechargeable battery was the most economical at the beginning of the two 2000s. It largely dominated the hybrid vehicle market until the advent of lithium-ion technology.

Nickel metal hybrid batteries used routinely in computer and medical equipment of reasonable specific energy and specific power capabilities nickel metal hybrid batteries have a much longer life cycle than lead acid batteries and are safe and abuse tolerant.

Now let’s see the advantages and disadvantages of nickel-metal hybrid batteries.

| Sr.no | Advantages Of Nickel-Metal Hybrid Battery for Electric Car Conversion |

| 1 | Double energy density compared to lead-acid batteries. |

| 2 | Harmless to the environment. |

| 3 | Easily recyclable. |

| 4 | Safe operation at high voltage. |

| 5 | It can store volumetric power and energy. |

| 6 | Cycle life is longer. |

| 7 | The operating temperature range is long. |

| 8 | It is resistant to overcharge and discharge. |

| Sr.no | Disadvantages Of Nickel-Metal Hybrid BAttery. |

| 1 | With a reduced lifetime of around 200-300 cycles, it discharged rapidly on high currents. |

| 2 | High self-discharge and heat generation at high temperatures. |

| 3 | Reduced usable power because of memory effects. |

Lead-Acid Battery for Electric Car Conversion

Lead acid batteries are one of the oldest kinds of rechargeable batteries. This battery is still found in many vehicles with both combustion and electric engines. In 1899 the electric car legume’s content featuring this technology was the first automobile to exceed 100 km/h.

Well before combustion engine vehicles compared to hybrid nickel metal or lithium-ion batteries, these are a lot heavier and eventually lose capacity. However, automobile companies still use it mainly because of its cheap pricing. In addition, since they have been using the technology for the longest time, the technology around the fitting and using the batteries more effectively has also involved making a better end product.

These days lead acid batteries are no longer used for traction but for power, the electrical circuit of accessories or components specific to combustion engines like the starter lead acid batteries only offers a limited capacity despite its significant bulk and weight but it is both expensive and easy to produce and recycle used as the primary energy storage mechanism for electric cars until the 80s it quickly gave way to other more efficient technologies.

Advantages Of Lead Acid-Battery to Select Battery for Electric Car Conversion

- It is available in production volume.

- Comparatively low in cost.

- It was a mature technology that was used for over fifty years.

Disadvantages Of Lead-Acid Battery.

- It cannot discharge more than 20% of its capacity.

- It has a limited life cycle if operated on a deep rate of the state of charge.

- Low energy and power density.

- It is heavier.

- It may need maintenance.

Solid-State Battery for Electric Car Conversion

Scientific research has long been exploring the concept of the solid-state battery. Still, it’s only in the last 10 years that its progress has made it possible to envisage the technology’s adoption by the automotive industry in the distant future. The principle behind it consists of replacing the battery’s liquid electrolyte with a solid material that can take the form of a plastic polymer compacted in organic powders or a mixture of the two.

In theory, this technology is all positive; it makes it possible to increase energy density and stability while making temperature control more manageable. Nonetheless, the solid state is still at the laboratory prototype stage and the lithium-ion battery still has a lot of life left in it.

Advantages Of Solid-State Battery for Electric Car Conversion

- Capable of delivering 2.5 times more energy density as compared to lithium-ion batteries.

- Comparatively more durable and safe.

- Less expensive and compact in nature.

- The recharge rate is 4 to 6 times more than regular ones.

- The greater electrochemical stability of these batteries makes them more reliable.

Disadvantages Of Solid-State Battery.

- Mass production and manufacturing are quite complex.

- Research is still in progress and the perfect material for the electrolyte with an ideal ionic conductivity is yet to be found.

Nickel Cadmium Battery for Electric Car Conversion

If you used rechargeable batteries in the 90s you’re already familiar with nickel nickel-cadmium neology. NickeNickel-cadmium had plenty of advantages with significant storage density and a lifespan of around 500 to 1000 charging cycles. However, they did suffer from the memory effect, a physical phenomenon that sees the battery’s performance decline if it is subject to partial charge drain cycles.

It was used for the production of electric vehicles in the 90s nickel-cadmium batteries are now prohibited due to the toxicity of cadmium.

Advantages Of Nickel-Cadmium Battery for Electric Car Conversion

- Long life.

- It can discharge fully without being damaged.

- It is easily recyclable.

Disadvantages Of Nickel-Cadmium Battery.

- Cadmium can cause pollution in case of not properly disposed of.

- It is costly for vehicular applications, what do you think about these batteries which are the best battery options for boosting electric vehicle performance?

Why Is The Most Expensive Electric Car Battery For Electric Car Conversion?

While it is true that electric cars lose battery capacity over time the continuing advances in technology and the precise degradation is difficult to define as a whole. The main factor is all down to the owner and how they treat their battery, the way energy is to be removed and how many charging cycles the battery experiences.

But in this topic, we are going to discuss what is the most expensive electric car battery to replace. So let’s get started.

As a whole, the Ford Mach-E battery replacement cost is around $25,319. It is far more expensive than a normal electric car battery. On the other hand, if we take a look at cheap battery replacements that cost you around $17,588. And the labor cost for battery replacement is about $1,200. And it’s all for just one battery.

Here are several factors that help batteries to stay healthy.

First, this may seem slightly counter-intuitive but Lithium batteries don’t like to be fully charged. That’s because heat is the enemy of the battery system and lots of heat is generated by both rapid charging and keeping the battery at high voltage. While batteries like to be cycled and used the general rule is not to be too reliant on rapid charges nor to overcharge the battery or let it completely flat.

The risk here is that dendrites can form which are kind of like weeds in the garden of battery chemistry and can cause failure. Instead, it’s advised that owners should always try to charge their electric vehicles. In the happy middle ground between 20 and 80 percent lots of heat also is produced if you like showing off to your friends how quickly your electric car can accelerate from a standstill.

Ludicrous Plus Mode

When you select a ludicrous plus mode on a Tesla it actually warns you that you’ll be impacting the battery life fortunately most electric cars are fitted with sophisticated battery management systems that can regulate if you’re doing too many drag races as well as create an artificial buffer at the top and bottom of the battery’s capacity to ensure cells in the battery pack won’t overcharge or over-discharge.

The battery management system in performance electric vehicles like the Porsche taken for example can even work with satellite navigation so it knows to precondition the battery when approaching a charging station.

Ambient Temperature

Ambient temperature is another factor that needs consideration because extreme heat and cold can negatively impact the car’s battery life. This is where battery packs that feature active thermal management degrade less than those that rely on air cooling because they’re better at maintaining a stable temperature range for the battery. car makers are well aware that potential buyers are concerned about the longevity of electric car batteries.

This is why these specific warranties often far exceed a typical vehicle warranty. There is no better example than the new Lexus UX 300e, which is the first vehicle to feature a 10-year 1 million kilometer warranty on the battery pack, and if that’s not confidence in the technology we don’t know what is.

Conclusion.

Conclusion#1: Factors to select battery for electric car conversion

In conclusion, These are the factors that help you to select a battery for electric car conversion. Required Driving Range, Battery Power Calculation, Operating Temperature And Battery Chemistry, and Spatial Constraints For The Battery Pack.

Conclusion#2: Nissan Leaf Battery for Electric Car Conversion

A YouTuber who converted a Nissan Leaf battery into his electric truck. First, he took out the whole battery. After getting all the car parts and batteries out he started salvaging the battery for himself. He placed both the replacement set of batteries in front of him, the lead acid battery and the equivalent lithium-ion battery. Then he converted the battery to a Nissan leaf acid battery and took the first test drive successfully

Conclusion#3: Lithium-io Battery for Electric Car Conversion

If you are also converting the battery in your electric vehicle, then I will recommend you Lithium Ion Battery because. The lithium-ion batteries have operated between the temperature of 10 – 60 degrees Celsius. And it is perfect for places where temperature is not a problem. Lithium-ion battery chemistry has higher energy density currently available.

Conclusion#4: Specification of Lithium-ion Battery for Electric Car Conversion

If we talk about lithium-ion battery specification then it has many specifications A lithium-ion battery is installed in an electric vehicle that can easily run the vehicle for 200 – 300 miles on a single charge. The nominal voltage of lithium-ion batteries is between 3.2 to 3.7 V. Lithium-ion batteries are lighter than other cells, which also slightly increases the range of the vehicle.

Lithium-ion battery chemistry has a higher energy density than any battery technology today. Lithium Ion batteries also have a low self-discharge rate which is around 1.5-2%.

Conclusion#5: Capacity of Battery For Electric Car Conversion

Most electric vehicle battery capacity ranges between 40 to 60 ampere hours. The ampere-hour rating refers to the power and longevity of the battery. It also tells you how long your battery can last without charging. The ampere-hour rating is for a large battery, such as a car battery, which is generally 20 hours.

French physicist Gaston Plante invented the rechargeable lead battery in 1859. The technology is used to store energy through electromechanical processes since then it has made great progress. All the scientific work has had a similar goal to find the best possible compromise between the battery weight, storage capacity, production cost, recharging capacity, and environmental impact.

When the battery reaches the end of its working life, it is recycled, which typically involves separating out valuable materials such as cobalt and lithium salts, stainless steel, copper, aluminum, and plastic. Only up to 50% of the material is recycled in the battery pack of an electric vehicle.

FAQs

What Are The Three Types Of Battery Most Commonly Used In Electric Vehicles?

By the way, there are a lot of batteries, but in today’s time, the one that is used the most and also the most popular battery is these three Lithium-Ion Batteries, Nickel-Metal Hydride Batteries, and Lead-Acid Batteries. These batteries are most commonly used in electric vehicles also these are most popular.

What Size Battery Do I Need For An Electric Car?

Recently, The battery capacity of a normal electric car ranges between 60 to 100 KWh. But in the coming times, we will see 130 to 200 batteries, according to automakers which is an unbelievable figure.

What Is The New Battery Technology For Electric Vehicles?

Lithium ferrous phosphate (LFP) batteries are a new battery technology. The special thing is that it is cheaper than nickel and cobalt batteries and this battery is also being used and contained in the US and europe.

Who Has The Best Battery Technology For EV?

Catl has the best battery technology for electric vehicles; he also dominates one-third of the electric vehicle market. Catl is a Chinese company. Its margin was 32 percent in 2021 and in 2022 it was increased by 34 percent.

What Are The Disadvantages Of Lithium-Ion Battery.

Here are some disadvantages of lithium-ion batteries: Lithium-ion batteries are sensitive at high temperatures. If the battery is completely discharged, it can no longer be recharged. and It is relatively expensive.

These are disadvantages but the advantages of lithium-ion batteries are much more than the disadvantages.

What Type Of Battery Does Tesla Use?

Tesla uses lithium-ion phosphate batteries (LFP) in their standard-range electric cars. Tesla announced in 2021 that he was switching on lithium ion phosphate batteries. In all standard range cars like Model 3 and Model Ys.

Posts Related to Electric Car and Batteries

- What Do You Think Should Be the Minimum Range for Electric Cars?

- Hyundai Ioniq 12V Battery Replacement Cost

- How To Precondition Tesla Battery for Home Charging?

- What Is The Range Of A Mini Electric Car

- What Happens If My Tesla Runs Out Of Charge?

- How Electric Car Batteries are Recycled in California? Top 5 Ways of Recycling Electric Car Batteries in California- An ultimate guide 2024

- Tesla Model 3 Range City Vs Highway – Real Testing Done

- When Will Tesla Model 3 Get 4680 Battery-Ultimate Guide 2024

- How Are Tesla Batteries Recycled?

- Why Did My Model 3 Range Decrease?

- How long Tesla Battery Last?

- Electric Car Range At Different Motorway Speeds

- Chevy Bolt Battery Lifespan

- Everything about Electric Car Battery – Complete Guide 2024